Poly Electrolytes are widely used today as essential coagulants and flocculants in industrial water treatment, municipal wastewater plants, petrochemical facilities, sludge dewatering units, and sedimentation systems. Although many specialists can identify the correct type of poly electrolyte for their process, the real challenge lies in how to apply the product correctly. Incorrect usage leads to material wastage, lower efficiency, increased TSS, poor sludge formation, and higher operational costs.

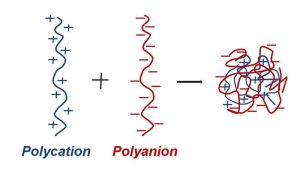

Difference Between Cationic and Anionic Poly Electrolytes

Cationic Poly Electrolyte

Used in:

Municipal and industrial wastewater

Sludge dewatering equipment (filter press, centrifuge, belt press)

Wastewater containing organic and negatively charged particles

Anionic Poly Electrolyte

Used in:

Sedimentation and flocculation

Paper, textile, and steel industries

Wastewater with mineral particles carrying a positive charge

This article focuses only on “how to use” the product, not on choosing the product.

How to Use Poly Electrolytes – Practical Instructions

Preparing the Poly Electrolyte Solution

Preparing a proper stock solution is the most critical step. Poly electrolytes are lightweight powders and if not dissolved properly, they form lumps and lose efficiency.

Standard Solution Concentration

Powder product: 0.1% to 0.5%

(100–500 g per 100 liters of clean water)

Correct Preparation Steps

Fill a clean tank with water (preferably 25–35°C).

Turn on the mixer at low speed.

Sprinkle the powder slowly over the vortex surface.

Mix gently for 30–45 minutes.

Allow the solution to mature for 30 minutes before injection.

Golden Rule: Immediate use of fresh solution reduces floc strength and increases chemical consumption.

Determining the Proper Dosing Rate

The dosage varies depending on COD, TSS, suspended solids type, organic load, and system design.

Typical Consumption Range

Cationic: 0.5–3 g/m³

Anionic: 1–5 g/m³

Dosing Procedure

Conduct a Jar Test.

Start with the lowest feasible dose.

Increase step-by-step until optimum floc formation appears.

Adjust dosage daily depending on wastewater quality.

Application in Different Treatment Units

Sedimentation (Clarifier)

How to Apply:

Inject anionic solution into the rapid-mix line.

Provide 30–60 seconds of gentle agitation.

Avoid high shear mixers.

Adjust dose if outlet turbidity increases.

Correct Usage Indicators:

Lower TSS

Strong flocs

Reduced alum or ferric consumption

Filter Press & Sludge Dewatering

Cationic poly electrolytes are ideal for sludge dewatering units.

Usage Steps

Prepare a 0.1–0.3% solution

Start with a low injection rate

Inspect the filter press cake

Adjust dose until cake is solid and uniform

Signs of Correct Dosing

Higher dewatering speed

Drier cake

AXReduced sludge volume

Incorrect Dosing Signs

Sticky and soft cake

Cloth clogging

High chemical waste

Application in Petrochemical and Industrial Plants

Usage Method

Perform a jar test to determine charge type

Choose the right injection point

Adjust pH beforehand

Monitor floc behavior in contact tank

Use in DAF Systems

Proper Usage:

Inject cationic solution after primary coagulants

Allow 20–40 seconds of contact time

Adjust air flow

Observe floating flocs formation

Common Mistakes in Using Poly Electrolytes

High mixer speed

Over-concentrated solution

Direct injection of powder into the system

Neglecting jar test after wastewater changes

Using the chemical without pH adjustment

Safety Recommendations

Use gloves, goggles, and a mask

Avoid contact with eyes

Store solution less than 24 hours

Add powder in a wind-free area

Performance Optimization Tips

Prepare fresh solution

Clean dosing lines regularly

Review dose weekl

Use high

molecular weight grades for oily wastewater

Always request a sample before mass purchase

Conclusion

Correct solution preparation, dosing control, injection point selection, and contact time significantly improve performance. Proper usage results in:

Lower treatment costs

Faster sedimentation

Cleaner effluent

Higher dewatering performance

No comment